Introduction

We'll start by prepping parts that require loctite/glue so that they have time to set.

-

-

Warning: The Loctite 410 can be messy, we recommend covering your workspace with something disposable to protect it.

-

Apply a thin layer of the Loctite 410 to the inside of the nut well.

-

Gently slide an M3 Lock Nut into the nut well, ensuring that the locking side (the white ring) faces upward.

-

Repeat for the remaining two Idler Subassemblies, for a total of three.

-

-

-

Apply a light line of Loctite 410 to the inside channel of the Ball Rail Carriage Top.

-

Press an M3 37mm Standoff into the Loctite.

-

Repeat for the two remaining Ball Rail Carriage Top, for a total of three.

-

-

-

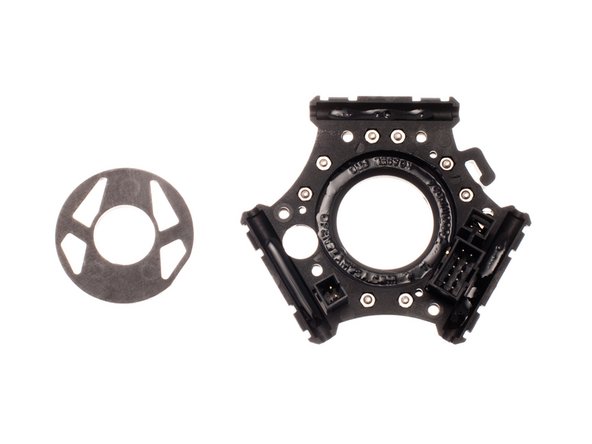

Apply a thin line of Loctite 410 into each channel of the End Effector Bottom, and along the inside ring.

-

Press the End Effector Interior Duct into the center, paying careful attention to it's alignment.

-

Press M3 37mm Standoffs into each channel.

-

Set completed parts aside to cure.

-

Cancel: I did not complete this guide.

One other person completed this guide.